History lives on

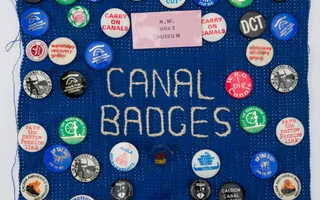

Many of our canals were built at the height of the Industrial Revolution, and thanks to the hard work of our dedicated heritage, collections and archive teams, the history of our canals can live on.

Just like the incredible structures dotted along the canals, there are stories of the people who worked the boats during the glorious Canal Age, the boating families, and pioneering engineers without whom the canals would never have existed.

Vital role

We understand the vital role our canals and rivers have played in the history of England and Wales and treasure these tangible signs of the past. At the same time, we look to the future and the benefits our canals bring to society today.

Our waterways never stop moving, and we never stop working to help them thrive.